Originally Posted by

lysander

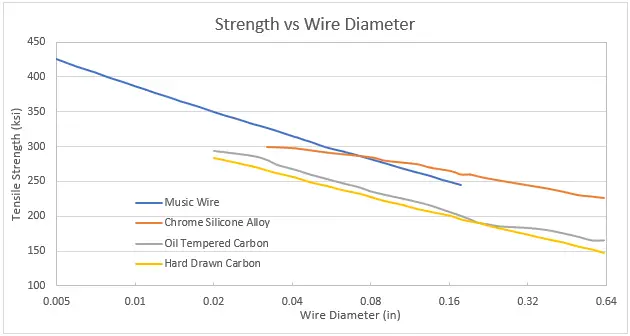

People don't understand CS spring are pointless in a firearm. CS springs are no better than music wire, unless the environment is above 350° F. They are great for valve springs in engines because the internal temperature can be that high and since they live in a oil bath corrosion is not an issue.

Music wire and CS are better than stainless steel for life, but the benefits of corrosion resistance far outweigh that.

I think the main reason people like the Sprinco action springs is because they are customizable with all the different size gas ports that are out there in the commercial market.

Not sure why Sprinco chose CS over stainless steel unless it was just the long life benefits.

You won't outvote the corruption.

Sic Semper Tyrannis

Bookmarks